In this unit will be presented, in an experimental set-up, the contribution that digital fabrication technologies can offer in the Textile field to explore new types of conceivable products and processes.

In particular, starting from an excursus that identifies the democratization of technologies, the customization of production and the independence of distribution as real drivers of change, the focus will be on the demonstration of possible experimental applications, through the exposure of case studies developed within makerspaces and Fab Labs.

Indeed, these places are structured in order to encourage the dynamics of learning by doing, where the trial-and-error learning represents a fundamental process that allows individual and collective knowledge to grow. Since these are realities outside of industrial mechanisms, it is possible to give life to new experiments, which push the boundaries of the intrinsic limits and opportunities of the technologies used, enhancing and finding new ways of interpreting them.

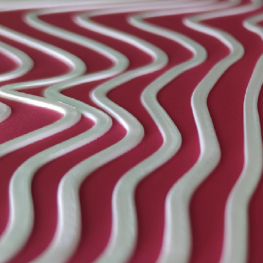

During the contribution, case studies will be presented that synthesize design and production strategies employing both additive (3D printing) and subtractive (laser cutting) technologies. These can be considered as inspirations able to act as a driver for scalable applications in industrial sectors that envision textile integration both as a priority element and as a sub-product.

Keywords: digital fabrication, additive manufacturing, laser cutting, 3D printing textile, auxetic structure